Ihame ryo gutunganyaLaser ya semiconductor ishobora guhindurwa(Lazeri ishobora guhindurwa)

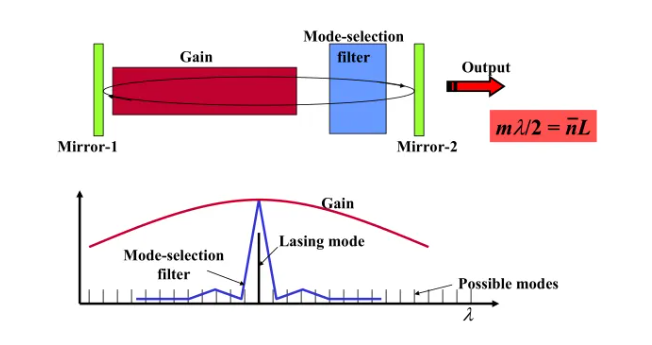

Laser ya semiconductor ya Tunable ni ubwoko bwa laser ishobora guhindura buri gihe uburebure bw'umuvuduko wa laser mu rugero runaka. Laser ya semiconductor ya Tunable ikoresha uburyo bwo gupima ubushyuhe, gutunganya amashanyarazi no gutunganya ibyuma kugira ngo ihindure uburebure bw'aho utuye, spectrum yo kugarura urumuri, phase n'ibindi bintu kugira ngo igere ku buryo bwo gupima uburebure bw'umuvuduko. Ubu bwoko bwa laser bufite uburyo bwinshi bwo gukoresha mu itumanaho ry'amajwi, spectroscopy, sensing, ubuvuzi n'ibindi. Ishusho ya 1 igaragaza imiterere y'ibanze yalaser ihindurwa, harimo igice cyo gukura urumuri, umwobo wa FP ugizwe n'indorerwamo z'imbere n'iz'inyuma, hamwe n'igice cyo guhitamo uburyo bw'urumuri rwa optique. Amaherezo, iyo uhinduye uburebure bw'umwobo wa reflection, akayunguruzo k'uburyo bw'urumuri gashobora kugera ku musaruro w'ihitamo ry'uburebure bw'umuraba.

ISHUSHO YA 1

Uburyo bwo gukosora n'inkomoko yabwo

Ihame ryo gutunganya ibintu mu buryo bwo guhindura ibintulaser za semiconductorahanini biterwa no guhindura ibipimo by’umubiri bya resonator ya laser kugira ngo habeho impinduka zihoraho cyangwa zitandukanye mu muvuduko w’ubugari bwa laser. Ibi bipimo birimo, ariko ntibigarukira gusa kuri, index ya refractive, uburebure bw’aho utuye, n’uburyo bwo guhitamo. Ibi bikurikira birambuye ku buryo butandukanye bwo gutunganya n’amahame yabwo:

1. Gutunganya inshinge z'imodoka zitwara imizigo

Guhindura imiterere y’icyuma gitwara umuriro ni uguhindura imiterere y’icyuma gitwara umuriro gishyirwa mu gace gakora ka laser ya semiconductor, kugira ngo hagerwe ku gukosora uburebure bw’umuraba. Iyo uburebure bw’umuraba bwiyongere, ubwinshi bw’icyuma gitwara umuriro mu gace gakora buriyongera, bigatuma habaho impinduka mu miterere y’icyuma gitwara umuriro, ibyo bigatuma uburebure bw’umuraba bwa laser bugira ingaruka ku miterere y’icyuma gitwara umuriro.

2. Guhindura ubushyuhe Guhindura ubushyuhe ni uguhindura uburebure bw'igipimo cyo kugarura ubushyuhe n'uburebure bw'igipimo cyo kugarura ubushyuhe bw'icyuma gikoresha laser, kugira ngo habeho gukosora ubushyuhe bw'uburebure bw'urumuri. Impinduka mu bushyuhe zigira ingaruka ku gipimo cyo kugarura ubushyuhe n'ingano y'ikintu.

3. Gutunganya ikoranabuhanga Gutunganya ikoranabuhanga ni uguhindura uburebure bw'umurambararo w'urumuri binyuze mu guhindura aho ibintu by'inyuma by'urumuri bya laser biherereye. Uburyo busanzwe bwo gutunganya ikoranabuhanga burimo guhindura ingano y'urumuri rw'urumuri no kwimura aho indorerwamo iherereye.

4 Gutunganya amashanyarazi Gutunganya amashanyarazi bigerwaho hakoreshejwe amashanyarazi ku bikoresho bya semiconductor kugira ngo bihindure igipimo cyo kugarura ubushyuhe bw'ibikoresho, bityo bigere ku gukosora uburebure bw'umuraba. Ubu buryo bukunze gukoreshwa murimodulators z'amashanyarazi n'amatara (EOM) na laser zikoresha amashanyarazi.

Muri make, ihame ryo gutunganya rya laser ya semiconductor ihindura uburebure bw'umurambararo w'ikirere rikorwa ahanini mu guhindura imiterere y'ubuso bw'umurambararo binyuze mu guhindura ibipimo by'umubiri bya resonator. Ibi bipimo birimo index ya refractive, uburebure bw'aho utuye, n'uburyo bwo guhitamo. Uburyo bwihariye bwo gutunganya burimo gutunganya inshinge z'umuyoboro, gutunganya ubushyuhe, gutunganya ibyuma n'uburyo bwo gutunganya amashanyarazi. Buri buryo bufite uburyo bwabwo bwihariye bwo gutunganya imiterere n'imibare, kandi guhitamo uburyo bukwiye bwo gutunganya bigomba gusuzumwa hakurikijwe ibisabwa byihariye, nko gukosora urwego rw'umurambararo, umuvuduko wo gutunganya, ubushobozi bwo gusubiza ibintu mu buryo n'ubudahangarwa.

Igihe cyo kohereza ubutumwa: Ukuboza 17-2024